Designing today the Low-carbon machines of tomorrow

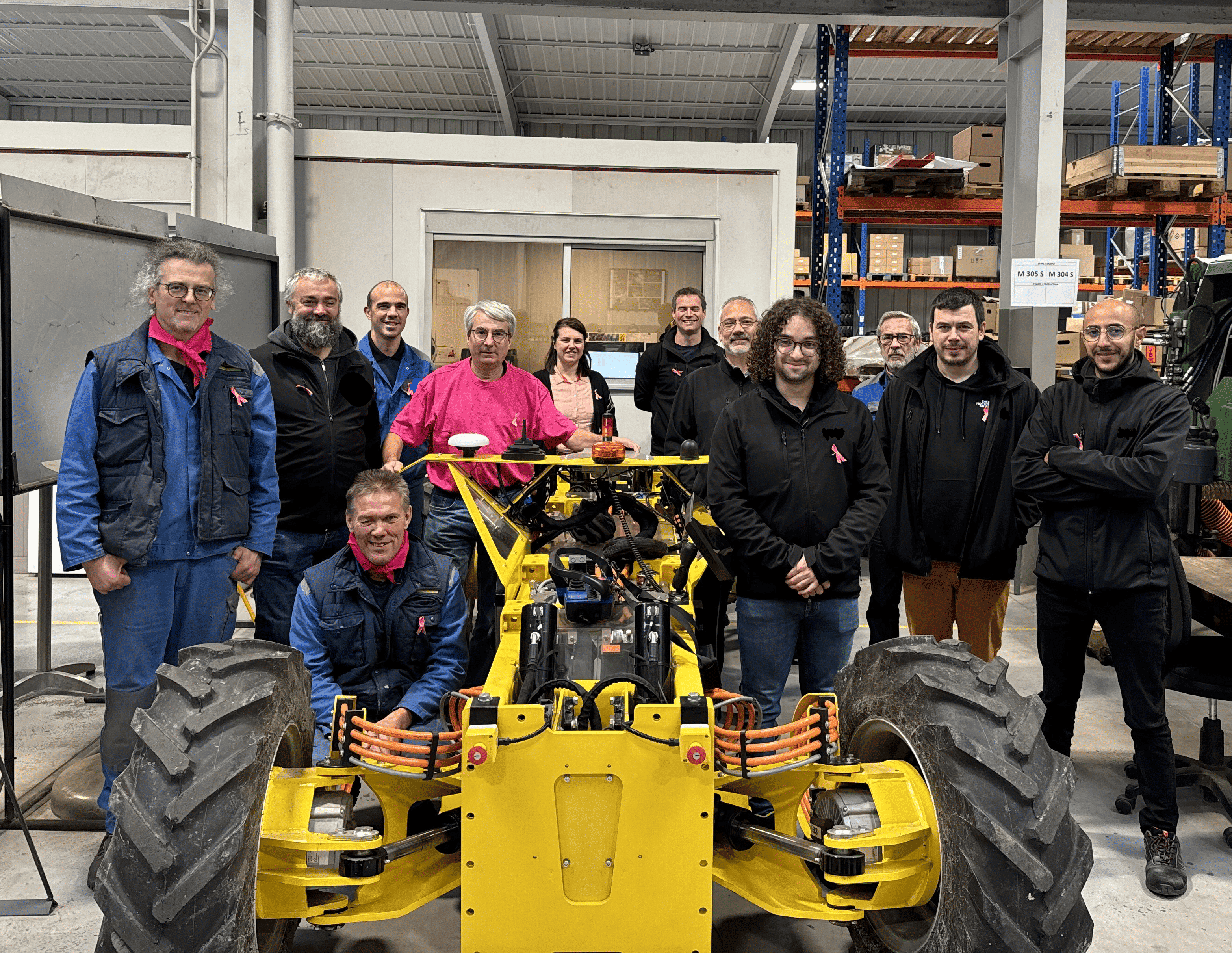

Kinell helps manufacturers of agricultural, construction and materials-handling machinery make their equipment lower-carbon and smarter.

Our expertise covers every stage of the process: mechanical design, robotics, embedded software, prototyping, and the manufacture of bespoke components. We work to accelerate the energy transition, reduce carbon footprints and deliver higher-performance machines.

We are a human-scale team united by a shared passion for innovation and engineering. Roles are clearly defined, yet offer a wide variety of responsibilities and a high level of autonomy.

Work is carried out in a collaborative environment: engineers, technicians and experts work hand in hand on increasingly exciting and innovative projects. Freedom of expression, fast decision-making and direct access to senior management foster an agile and responsive way of working.

We are looking for people who enjoy teamwork and project-based work, and who are motivated to contribute to a more sustainable future.

Our key figures

-

2004

Year of creation

-

49

Employees

-

2 sites

at La Chevrolière

-

43

Average age

-

96%

Permanent contract

-

14%

Women

Testimonial : Valentin, Electrohydraulic Technician

“When I first joined, my main responsibilities included assembling new components and carrying out adjustments on test benches. Over time, my skills developed, enabling me to handle more complex customer after-sales requests — ranging from non-conformity management and technical advice to the diagnosis, repair and expert assessment of hydraulic and electronic components.

I am also involved in commissioning complete machines or sub-assemblies at customer sites, working alongside the engineers who developed these projects.

My days are shaped by the wide range of customer calls and requests. Their diversity allows me to discover new systems and sub-assemblies on a daily basis and often requires additional research to provide the most effective solutions. I am particularly motivated by the customer interaction, whether over the phone or on site during after-sales interventions. I also value the friendly working atmosphere, the mutual support when challenges arise, and the availability of my colleagues to answer any technical questions.

My three words to describe my experience at Kinell: enriching — thanks to the variety of assignments, flexibility at work, and the continuous development of my technical skills.”

Testimonial : Cyril, Prototypist

“As a Prototypist, I work on a wide range of projects. Our machines are now designed around modular sub-assemblies (such as hydraulic modules, control cabinets and energy packs) to make assembly easier. The integration of new components and technologies requires a high level of rigour from the prototyping stage onwards, with a view to pre-series production and after-sales support.

In this context, I need to be versatile and adaptable, working closely with the various departments across the company — in particular the design office teams, including mechanical design, electrical engineering and software.

What motivates me most in my role is the diversity of tasks and the collaboration with all departments. Finding solutions, contributing to the development of the machine and seeing a project through to completion is highly rewarding.

My three words to describe my experience at Kinell: innovation, project diversity and team cohesion.”

Testimonial : Vincent, Prototyping Workshop Manager

“I joined Kinell in 2012, recruited to set up an assembly line for a road maintenance machine — which involved organising the workshop, preparing tools, managing assembly orders, and performing final assembly inspections.

My current role is to support the design office engineers in making technical decisions for our projects, selecting the components best suited to our clients, and assembling machine prototypes, covering mechanical, electrical and hydraulic assembly.

Patience, perseverance, passion and collaboration with specialists from related fields motivate me every day.

My three words to describe my experience at Kinell: discovering new technologies, continuous learning, and team relationships.”

Our Location

Our offices and workshops are located in a small rural town, just a 20-minute drive south of Nantes.

We operate from two sites in La Chevrolière (44):

-

Bois Fleuri Zone: Project and Manufacturing departments

-

Tournebride Zone: Sales, Marketing and Supply Chain departments

🚗 Access and Transportation

The sites are primarily accessible by car. To make commuting easier, we encourage carpooling among colleagues.

Public transport is also an option via Cars Aléop:

-

Aléop Line 312, stop: Zone Industrielle, 7 minutes’ walk from our Bois Fleuri site

-

Aléop Line 313, stop: Tournebride – La Chevrolière, 10 minutes’ walk from our Tournebride site

View our Jobs and Apply

EN

EN

FR

FR